60 Rubber rail pad

发布时间:2022-06-17 09:02:40 浏览量:615

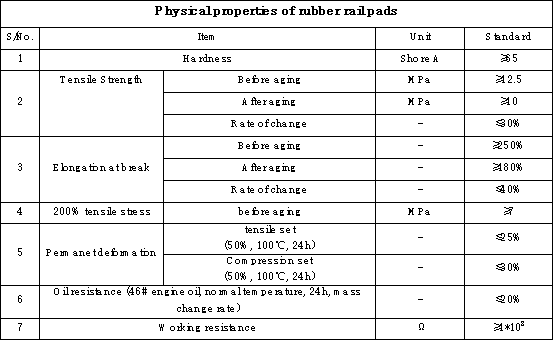

The rubber rail pad for railway track structure (hereinafter referred to as "rubber rail pad") is an important component in the track structure. It is installed between the steel rail and the concrete sleeper. Its main function is to buffer the high-speed vibration and impact generated by the passing of vehicles. Protect the roadbed and sleepers, and electrically insulate the signal system. In addition, the rubber backing plate is required to have good natural aging resistance, cold resistance and heat resistance because it is exposed to the atmosphere for a long time. The rubber backing plate has good shock absorption and noise reduction, etc. performance.

Features of rubber rail pads:

1. Strong shock absorption, anti-aging, wear resistance, stability, high and low temperature resistance, products include natural rubber, styrene-butadiene rubber, neoprene, HDPE, EVA, high-density polyethylene and other combinations, product elasticity High, and not easy to deform or break at various temperatures.

2. Long service life and low maintenance and replacement costs.

3. It is suitable for the laying of various rails such as 43KG, 50KG, 60KG, and various sleepers such as wooden sleepers and concrete sleepers.

4. Anti-shock performance, good insulation performance, wear-resistant, less deformation after repeated compression, anti-aging, long service life and easy installation. The use of railway rubber pads can greatly improve the transport capacity of motor vehicles.

Rubber backing plate is made of rubber as the main raw material, scientific formula and high-tech production technology. The rubber backing plate meets the requirements of railway acceleration, shock absorption and buffering.